Artificial Intelligence (AI) is no longer a futuristic concept reserved for science fiction. It’s here, it’s real, and it's revolutionizing industries across the globe.

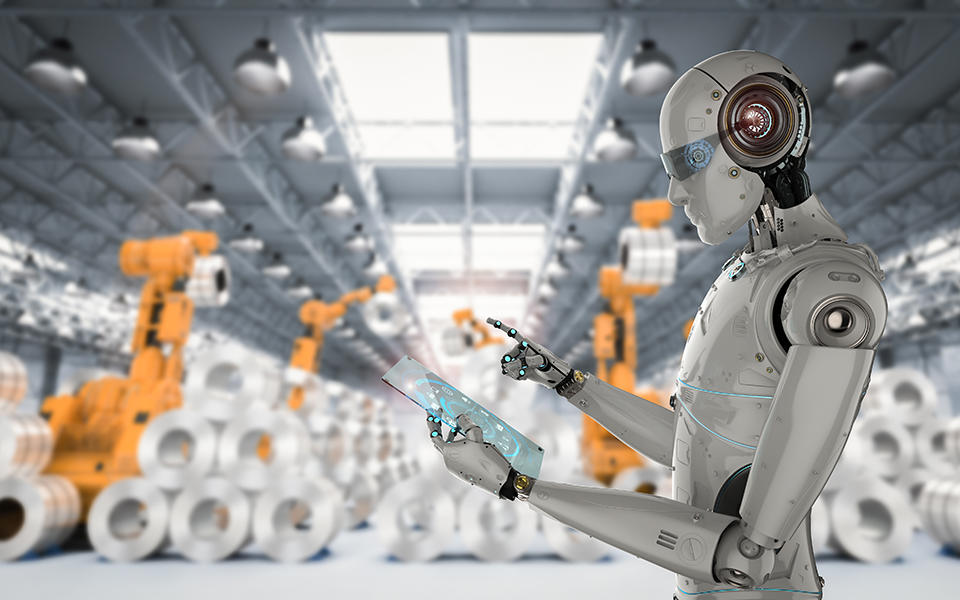

One sector where AI is making a significant impact is manufacturing. From optimizing production processes to enhancing quality control, AI is driving a new era of efficiency and innovation.

AI and the Smart Factory

The term "smart factory" is becoming more prevalent as AI integrates deeper into manufacturing. In a smart factory, AI systems analyze vast amounts of data from sensors, machines, and other devices to optimize operations.

This leads to reduced downtime, improved productivity, and lower costs. For instance, predictive maintenance powered by AI can foresee equipment failures before they happen, allowing manufacturers to address issues proactively rather than reactively.

This not only saves time and money but also extends the lifespan of machinery.

Enhancing Quality Control

Quality control is critical in manufacturing, and AI is transforming how it’s done. Traditional quality checks can be time-consuming and prone to human error.

AI, however, uses computer vision and machine learning algorithms to inspect products with incredible accuracy and speed. These systems can detect defects that are invisible to the human eye, ensuring that only the highest quality products reach the market.

This level of precision is particularly valuable in industries like automotive and electronics, where even minor defects can have significant consequences.

Streamlining Supply Chains

AI is also reshaping supply chain management. By analyzing patterns and predicting future demands, AI can optimize inventory levels, reducing both excess stock and shortages.

This predictive capability is crucial for just-in-time manufacturing, where materials and components arrive exactly when needed, minimizing storage costs and waste. Moreover, AI can help in

selecting the best suppliers by evaluating their performance, reliability, and cost-effectiveness, leading to more robust and efficient supply chains.

Improving Human-Machine Collaboration

One of the most exciting aspects of AI in manufacturing is the potential for enhanced human-machine collaboration. Rather than replacing human workers, AI-powered systems can augment their capabilities.

For example, collaborative robots, or cobots, can work alongside humans, handling repetitive or dangerous tasks. This not only increases safety but also allows human workers to focus on more complex and creative aspects of production.

Training programs powered by AI can also provide workers with personalized learning experiences, helping them to adapt to new technologies and roles.

Challenges and Considerations

While the benefits of AI in manufacturing are substantial, there are also challenges to consider.

The implementation of AI systems requires significant investment in technology and training. Moreover, there are concerns about data security and privacy, especially when dealing with sensitive information.

Companies must also address the ethical implications of AI, ensuring that it is used responsibly and that its impact on the workforce is managed carefully.

The Future of AI in Manufacturing

Looking ahead, the role of AI in manufacturing will only continue to grow. As AI technologies advance, they will unlock new possibilities for innovation and efficiency.

Manufacturers who embrace AI today will be well-positioned to lead in the future, reaping the benefits of smarter operations, higher quality products, and more resilient supply chains.

In conclusion, AI is not just a buzzword; it’s a transformative force in manufacturing. By leveraging AI, manufacturers can achieve unprecedented levels of efficiency, quality, and innovation.

The journey may be challenging, but the rewards are well worth the effort. As AI continues to evolve, it will undoubtedly shape the future of manufacturing in ways we can only begin to imagine.