Laser systems are ubiquitous in modern industries, from manufacturing and healthcare to entertainment and research. While lasers offer incredible precision and versatility, ensuring their safety is paramount.

Understanding the risks associated with laser systems and implementing proper safety measures are essential for protecting both workers and the environment.

Understanding Laser Classification

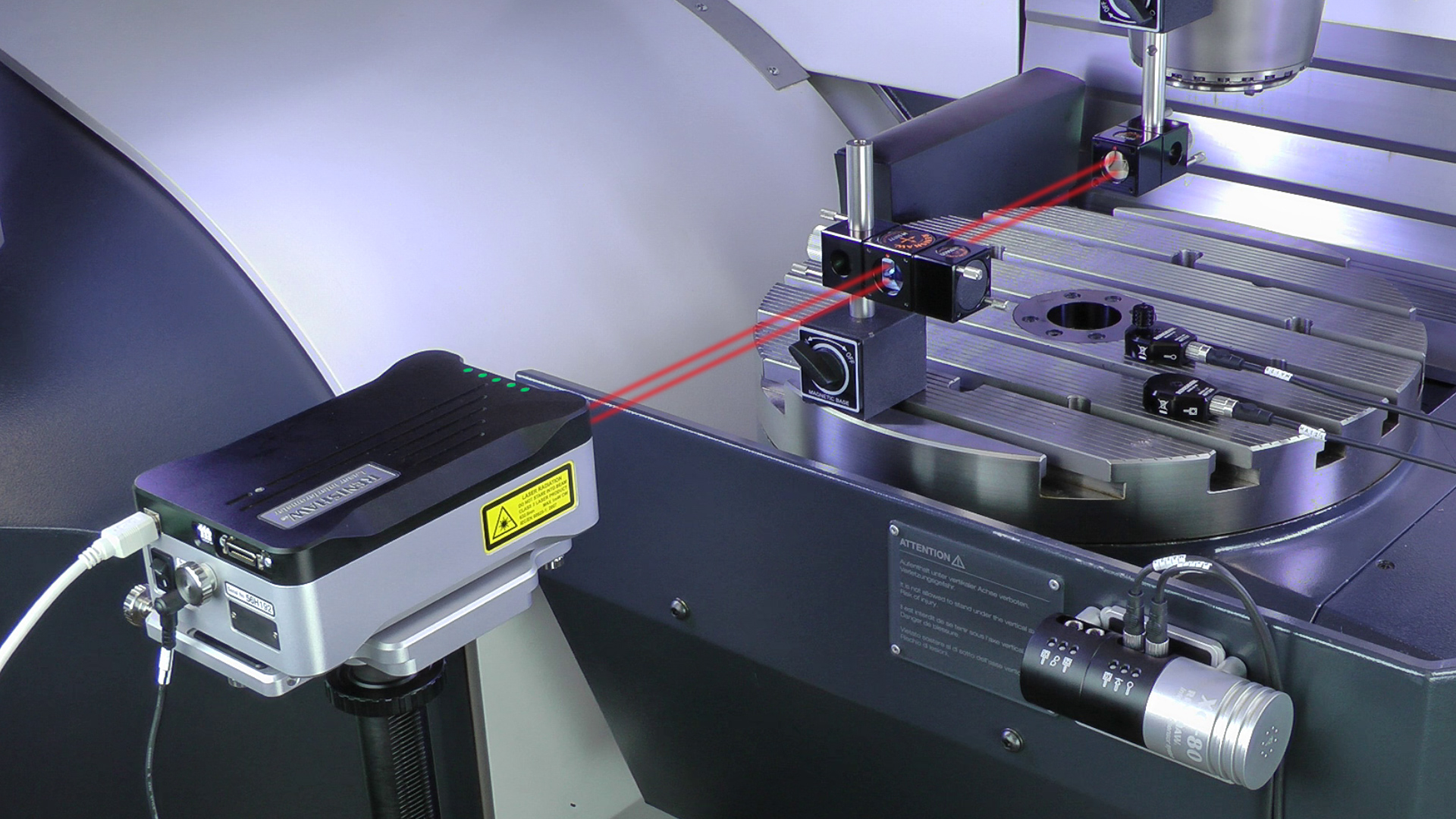

Laser systems are classified based on their potential hazards, including the wavelength, power output, and duration of exposure.

The classifications range from Class 1 (no hazard during normal use) to Class 4 (hazardous under direct or scattered radiation).

Each class has specific safety requirements to minimize risks to operators and bystanders.

Risk Factors and Hazards

The primary hazards associated with lasers include:

• Eye Hazards: Direct exposure to laser beams, especially high-powered lasers, can cause permanent eye damage or blindness. Even low-powered lasers can be hazardous if viewed directly for extended periods.

• Skin Hazards: High-powered lasers can burn or damage the skin upon direct contact. Operators must wear appropriate protective clothing and use shielding to prevent accidental exposure.

• Fire Hazards: Some lasers generate intense heat, posing a risk of fire if flammable materials are present nearby. Fire prevention measures, such as fire-resistant barriers and extinguishing systems, are essential in laser environments.

Safety Measures

Implementing effective safety measures is crucial to minimize laser-related risks:

• Engineering Controls: Use physical barriers, enclosures, and interlocks to prevent unauthorized access to laser beams. Ensure that laser systems are properly maintained and calibrated to reduce the risk of malfunction.

• Administrative Controls: Develop comprehensive safety protocols and training programs for laser operators and maintenance personnel. Educate workers on the risks associated with lasers and the proper use of personal protective equipment (PPE).

• Personal Protective Equipment (PPE): Provide appropriate eyewear and clothing designed to protect against laser radiation. PPE should be rated for the specific laser wavelengths and power levels present in the work environment.

• Warning Signs and Labels: Clearly mark laser-operating areas with warning signs indicating the laser class, hazards, and safety precautions. Ensure that all personnel understand and comply with these warnings.

Regulatory Compliance

Compliance with regulatory standards and guidelines is essential for maintaining laser safety. Organizations must adhere to regulations such as the Occupational Safety and Health Administration (OSHA) standards in the United States or the European Union's Machinery Directive.

These regulations establish minimum safety requirements for laser equipment, installation, operation, and maintenance.

Continuous Monitoring and Evaluation

Regular audits and safety assessments are critical to ensure ongoing compliance with safety standards and identify potential hazards or shortcomings in safety protocols.

Update safety procedures as technology evolves and new risks emerge.

Conclusion

While laser systems offer significant benefits in various industries, their safe operation requires diligent adherence to safety protocols and regulatory standards.

By understanding the risks associated with lasers, implementing comprehensive safety measures, and providing ongoing training and supervision, organizations can create a safe working environment for all personnel.

Prioritizing laser safety not only protects workers from harm but also safeguards equipment and ensures regulatory compliance in today's rapidly advancing technological landscape.